Why Choose Us?

Rich Experience

Hangzhou Wagen Precision Tooling Co.,Ltd is a wholly-owned subsidiary of Ferrotec China Group, a Japanese diversified multinational group. It was established in 2000 with a total investment of 867 million yen.

Advanced Equipment

WAGEN has the most advanced technology and equipment from Europe, America and Japan, and has established a complete service system of R&D, manufacturing, sales and after-sales.

Reliable Product Quality

WAGEN adheres to the corporate philosophy of "diligence, determination, pioneering, and excellence" of Ferrotec China Group, keeps making progress and innovation, and establishes a sophisticated process flow, is committed to passing on the brand concept and high-quality products to every customer.

Wide Range of Applications

Wagen Precision Products are widely used in producingspare parts of car and plane, Aluminum, Furniture, Wood and Plexiglas.

What is Saw Blade?

A saw blade is a steel tapered or toothed blade used in woodworking, metalworking, and other similar industries. Saw blades come in many different shapes, sizes, and grades depending on the intended use of the finished product. They can be used for cutting materials such as wood, plastics, metals, and composites.

-

120mm Japan Grooving Saw Saw Blade

Inventory name: Alloy circular saw blades. Specification and model:120*3.1-4.3*2.2*20*24P. Usage:

Add to Inquiry -

168mm Japan Ciucular Cutting Saw Blade

Inventory name: Alloy circular saw blades. Specification and model:168*3.5*2.5*50*18P.

Add to Inquiry -

250mm Japan Solid Wood Cutting Saw Blade

Inventory name: Alloy circular saw blades. Specification and model: 250 * 3.2 * 2.2 * 30 * 48P.

Add to Inquiry -

305mm Efficient Cutting Precise Saw Blade

Inventory name: Alloy circular saw blades. Specification and model: 305 * 3.2 * 2.4 * 60 * 100P;

Add to Inquiry -

255mm Japan High Quality Carbide Saw Blade

Inventory name: Alloy circular saw blades. Specification and model: 255 * 2.0 * 1.5 * 25.4 * 100P.

Add to Inquiry -

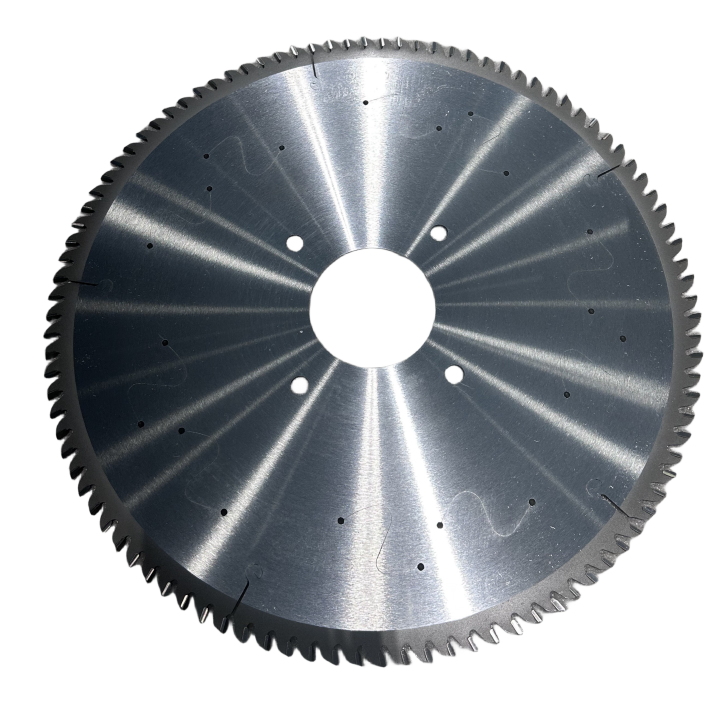

Professional High Quality Carbide Saw Blade

Stock Name:Alloy circular saw blade. Specifications: 255×2.2×1.7×25.4×135p. Electroplating:

Add to Inquiry -

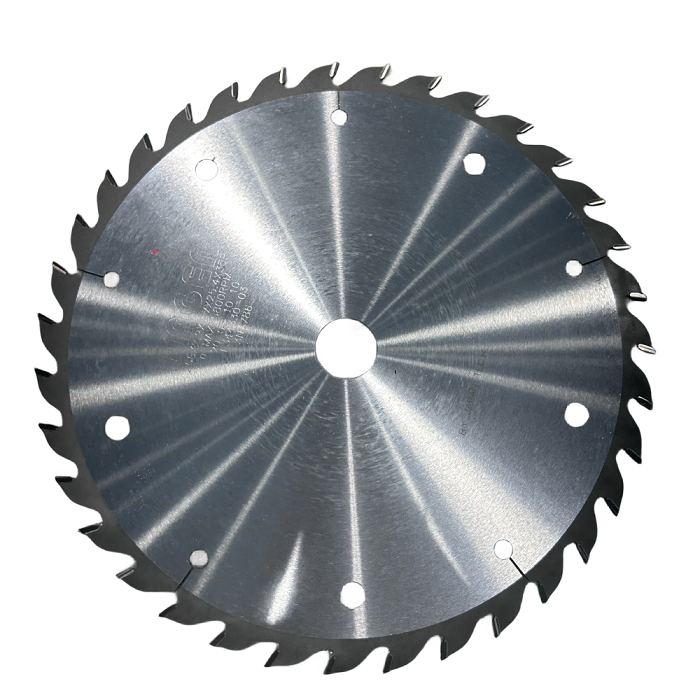

Industrial-grade Sharp And Durable Saw Blade

Stock Name:Iron Products. Specification model: 285×2.0×1.7×32×60p. Electroplating:N. Sealant:N.

Add to Inquiry -

Coated PVD-F Precision Circular Saw Blade

Stock Name:Iron Products. Specification model: 380×2.6×2.25×40×80p. Electroplating:N. Sealant:N.

Add to Inquiry -

Professional Round Saw Blade Hard Metal Alloy

Stock name: alloy circular saw blade. Specifications: 305×3.4×2.6×25.4×120p. Plating: chrome

Add to Inquiry -

Manufacturers Wholesale Metalworking Hard Machinery Circular Saw Blade

Stock name: alloy circular saw blade. Specifications: 305×3.0×2.2×25.4×100p. Plating: chrome

Add to Inquiry -

Wholesale WST-M Iron Cold Saw Blade Direct Sales

Stock Name:Iron Products. Specification model: 380×2.6×2.25×40×80p. Electroplating:N. Sealant:N.

Add to Inquiry -

Professional Solid Woodworking Saw Blade

Stock Name:Alloy circular saw blade. Specification model:205×3.0×2.0×30×80p. Electroplating:

Add to Inquiry

WAGEN is a Japanese-funded enterprise that develops, produces and sells high-end precision cutting tools such as WAGEN brand metal cold saws, aluminum alloy saw blades, carbide saw blades and diamond tools, which are widely used in automobiles, aircraft parts manufacturing, aluminum alloy profile processing, furniture manufacturing, wood processing, plexiglass processing and other industries.

Saw blade is a steel tool, commonly used to cut wood, metal or electronic cutting materials and other materials and machinery, saw blade is very versatile, there are a wide range of applications. For example, in building construction, saw blades are needed to cut steel bars and aluminum; In industrial production, saw blades can be used to cut a variety of materials to create a variety of parts and industrial products.

Advantages of Saw Blade

Wide Range of Sawing Applications

Circular saw blades consist of steel saw bodies with cermet and carbide-tipped teeth. The tips are then ground to match the application for which the blade is being used. Circular saws have a wide range of sawing applications such as: carbon steel, alloy steel, stainless steel, bearing steel, tool steel.

High cutting rates, low energy consumption, low material losses

Longer life and faster cutting are the main reasons why a shop would switch to circular blades. Carbide-tipped blades start off sharper and remain sharp much longer than steel alternatives because of their great wear and heat resistance. A sharper edge means less chipping and shattering with the higher feed rates. You won’t have to change your blade as often, saving you time and money over the long term.

Increased productivity

If you are tired of wasting money on saw blades with short life spans, circular saw blades are well worth the investment. Generally, they stay sharper for a more extended period. Making that dreaded blade change happen less often allowing the saw to stay running and your operator to focus on more important tasks.

Superb surface finish for secondary applications

Due to the durability and toughness of the blade, the edges can remain sharp for a considerable time. Only a sharp edge is capable of making smooth and clean cuts. The fact that cermet/carbide tips will stay sharp for a significant time will enable you to cut various applications smoothly. The precision cut of a circular blade helps to avoid kerf tear-out for smoother and more precise cuts. You spend less time fixing errors and finishing the surfaces all while minimizing your material waste.

Longer blade life = less downtime

Did you know that circular saw blades can last for thousands of cuts? Not only will you gain an advantage in cut times you also gain time from not changing a blade as often as your competitor. Let them change blades while your production jobs are going out the doors.

Hardened blade for repeatable accuracy

Do you know what the primary benefit of using a circular saw blade over a band saw blade is? Saw experts say it’s the ability to have fast and repeatable accurate cuts with a great surface finish. These saw blades are tough and capable of pushing through the material effortlessly.

Types of Saw Blade

Rip blades

Rip blades are the foremost common sort of saw blade. They're designed to be wont to cut pieces of wood along the grain. The cuts that they create won't be very smooth, but they're going to traverse wood faster than crosscut blades.

Crosscut blades

Saw blades designed to form cuts perpendicular to the natural grain in pieces of wood are called crosscut blades. These blades won't typically make cuts as fast as rip blades but will produce very smooth cuts; they're best fitted to woodwork projects that need a subtle finish.

Finishing blades

If you're performing on a project where you would like very smooth cuts, you'll probably want to use a finishing blade. There are fine-tooth finishing blades, which will typically have a minimum of 40 tpi and are designed to form smooth cuts. There also are paneling blades that are made specifically to chop through materials like plywood and wall paneling.

Nail cutting blades

When performing on renovations and projects involving reclaimed or used wood pieces, you'll often end up cutting woods that have hidden nails. In cases like this, you'll want to use a manicure blade as they're designed to be ready to cut lumber safely.

Metal cutting blades

These blades are designed for chopping through metal. When cutting through metal materials, aluminum sheets, metals studs, and steel pipes, it's best to use one among these specialized metal cutting blades.

Dry diamond blades

Every now then, you'll find that you need to cut materials like ceramic or porcelain. It may happen tons more often if you're doing tiling and masonry jobs. To chop through these sorts of materials, you'll need a dry diamond blade.

Dado cutting blades

Dado cutting blades are typically used with radial-arm or table saws. They're specifically made to chop dadoes and grooves, but they will even be wont to cut moldings and tenons, among other things. There are two sorts of dado blades: Adjustable dado blades, easy to use, and quick and stack dado blades known to form clean and accurate cuts.

Curved cuts—One of the biggest uses for band saw blades is to make curved cuts in a piece of wood. Because the band runs on a loop and stays stationary during operation, a smaller, portable saw is capable of cutting denser, larger pieces of wood.

Milling lumber—To mill lumber, you basically need to resaw a raw log along four of its planes. In most cases, the first cut will be the most difficult, and then it is a matter of cutting the rounds. Once you are done with this process, you can resaw your rough lumber using a band saw to your desired level of thickness.

Resetting boards—A band saw can cut multiple pieces of wood at once to make sure each has precisely the same angle.

Resawing—Resawing refers to cutting a singular piece of wood into two thinner pieces. You can use a band saw for resawing because the blade remains static to the table and the blade runs in a loop perpendicular to the saw’s teeth.

Key Components of a Band Saw Blade

Key Component #1- Blade Tooth Shapes

One critical factor behind achieving precision cuts made by a band saw blade lies in the shape of the tooth. Tooth shapes are a combination of rake angles and gullet shape. Two common tooth types are precision or claw/hook. The rake angle is a measure of the tooth face inclination to the work and can be negative, neutral, or positive. The precision-shaped tooth is a generalist shape and can be used for most sawing applications, while the slightly more aggressive claw/hook-shaped tooth is often used when increased cutting rates are desired. Negative rake-angled blades are excellent when cutting hardened materials.

Key Component #2- Blade Gullets

Have you ever wondered why a band saw blade has those U-shaped spaces between the teeth? They're called gullets, and they play a crucial role in keeping your cutting channel clean. You see, as the blade cuts through the metal, chips can start to accumulate. The chips, if not removed from the cut channel, will clog the blade. This greatly reduces the useful life of the tool. If the gullets are clogged, they will not carry the chips. This results in an increased load on the blade and the machine. It can contribute to the hardening of the material, blade bounce, stripping of teeth, and chips being welded to the blade. That’s where the gullets come in - they create space for the chips to be carried away from the cut preventing them from building up.

Key Component #3- Blade Width

The width of a band saw blade also plays a significant role in its performance. Thicker blades provide more stability, known as beam strength and can handle larger dimensions and tougher materials, while thinner blades are better for intricate radius cuts. The narrower the blade, the tighter the radius that can be cut. It is important to consider blade width based on the type of band saw machine, the material being cut, and specific application.

Key Component #4- Blade Tooth Material Considerations

Band saw blade teeth come in a variety of materials. The three most common are carbon steel, bi-metal, and carbide. Each material has its unique benefits and drawbacks. Carbon tooth steel blades are an affordable general-purpose option but may not last as long as the other choices. Bi-metal tooth blades are by far the most often used in metal cutting applications and offer a decent lifespan cutting a wide variety of materials from mild steel to tool steel. Carbide tooth blades are made from a harder material than bi-metal blades and can handle the most demanding cutting applications.

The Difference Between Ripping, Cross-Cut and Combination Saw Blades

Bare essentials: Ripping blades are better suited to long, straight cuts because they cut quicker. Cross-cuts are better for fine, smaller, slower cuts. Combination are a bit of both.

Ripping blades have large gullets (space between blade teeth) that help to remove the material and lessen kickback: These blades are removing strings of wood in addition to sawdust, which creates a more accurate cut with less friction and helps in reducing heat accumulation.

Cross-cut blades cut across the grain of the wood: This means they need a higher number of teeth to ensure smooth finishes and eliminate tear-out. These blades are mainly removing fine sawdust, so they don’t need large gullets.

Then you have combination blades: Like most general purpose blades, they do an okay job of ripping and crossing without attaining a professional level.

This can be cost: Effective for hobbyist woodworking – don’t get fooled into over-speccing for your project, sometimes you just don’t need it.

How to Change a Circular Saw Blade

Step 1: Remove the Battery or Unplug the Power Cord

Remove the batteries if the saw is cordless, or unplug the power cord if it is a corded saw. It is to ensure that the blades are changed safely.

Step 2: Set the Blade Guard and Arbor in Place

Pull the blade guard back and place the saw on a wooden surface. Press the arbor lock button on the top of the blade if the saw has one. The arbor is the pole on which the blade is mounted. Press the blade into the wooden surface if there is no lock button.

Step 3: Remove the Arbor Nut

The third step is to loosen the arbor nut using a wrench that comes with a saw. To loosen the nut on a direct-drive circular saw, turn the wrench counterclockwise; on a worm drive unit, turn the wrench clockwise.

Step 4: Replace the Blade and Insert the New Blade

Remove the old blade by sliding the upper blade guard on the saw. Place the new blade on the arbor of the saw, making sure the saw teeth face the rotational direction. If you're not sure, look at the arrow on the blade guard of the saw. Tight the arbor nut using a wrench. Make sure not to over-tighten the nut as you make cuts with it, the nut tends to tighten even more. So it will be difficult to loosen it the next time you change the saw blade.

Step 5: Testing

Replace the batteries or put the cord into your power outlet once the new blade is installed, and give it a test run to ensure everything is secure and working properly.

The Considerations for Buying Saw Blade

Blade size

While this may seem obvious, you may be surprised to learn that each tool requires the right diameter blade to match cutting requirements and specific RPM (speed) of both the blade and saw. Using the wrong diameter blade and mismatching the RPM can result in equipment damage and operator injury. When selecting your blade, check your power tool requirements and the blade label carefully.

Number of teeth

How many teeth should you have? It’s not a case of more is better. Too many teeth cause a slow cut and burning, while too few teeth will give a very rough and splintered cut. A good rule of thumb, regardless of the blade diameter or thickness of material, is to have 2 to 4 teeth in the material being cut. This will produce the smoothest cut, optimal chip removal, the least amount of friction, and less strain on your equipment. Most importantly, it’s also safer.

It’s all in the teeth

The teeth are the critical feature of any saw blade. The teeth determine the type of materials the blade can cut, how fast or controlled your cut will be, how smooth your finished cut will appear, and how long your blade will last. All EAB blades are designed to achieve optimal results regardless of the type of blade.

Carbide Grade or Type

The grade of carbide tooth will help determine the type of material to be cut and the expected life of a blade. You might think that a harder grade of carbide will hold its sharp edge longer and have a longer life. While this is true to a certain degree, it also depends on the sharpening and usage. Generally speaking, softer carbide tips are more shock resistant and while harder tips will hold an edge better, they’re more brittle. For example, C2 or C3 carbide blade tips are best for cutting wood and construction materials on job sites. C4 and C6 blade tips are best for cutting melamine, plastics and metal products.

Hook Angle

The hook angle is the amount of forward or backward lean of each tooth. A higher hook angle will give you a more aggressive and faster-cutting speed, ideal for ripping and crosscutting lumber. A low (less than 5°) or negative hook angle will give a smoother, slower cut, which is ideal when cutting hard or brittle materials such as melamine and metal materials. While low hook angle blades are ideal for crosscutting with mitre saws, they are not ideally suited for ripping on table saws.

1. Keep them sharp

The sharper your saw blades, the quicker and safer they will cut. They won’t snag as easily and can make your work more efficient. By either replacing them when they slow down, or learning how to sharpen them with a saw sharpener and regularly doing it you can prolong their lifetime.

2. Choose the right cleaning solution

A soap or detergent will not work if you use it to clean your saw blades. You can use an oven cleaner or a CMT blade cleaner. Make sure that all parts of the blade are soaked properly and wiped down often.

3. Scrub it properly not too rough

Scrubbing is important to remove the dirt that is sticking on the saw blade. You can use a toothbrush to scrub the blades but remember to do it gently. If you scrub it too hard or use an abrasive material, it can ruin the surface of the blade. Use something soft like a towel or toothbrush to be the most careful to avoid dulling it.

4. Inspect your blades before use

Before using a saw blade, do a quick once over on the entirety of it. Missing teeth blades can seem small, but make it more dangerous and likely to become stuck or kick back, potentially injuring you. It only takes 30 seconds, yet can save you time and keep you safe.

5. Store your blades properly

Cleaning and sharpening the saw blades help to fix the saw blades. However, by storing them properly you can reduce the maintenance later on by reducing dirt, debris, moisture and keeping them true and sharp. Find a method that works for you to keep them clean, and isolated so they are in reach and safe.

Magazine-Style Storage Rack

Essentially a rectangular wooden frame mounted to the wall with slightly slanted individual slots, the magazine-style rack is an excellent choice for storing a smaller collection of high-end saw blades and provides a unique look to your workspace.

Slide-Out “CD-Style” Box

Similar to the storage systems we use to keep our Compact Disks in, this type of box completely conceals your saw blades while keeping them organized and accessible.

Knife Block

This type of setup is like the wood block you keep your kitchen knives in, only large and robust enough to hold your heavy saw blades.

Pull-Out Drawer

Built right into your saw table, a pull-out drawer takes up minimal space and lets you reach for the blades you require without stepping away from your saw.

French Cleat Saw Blade Storage

This rack that holds everything from circular saw blades to bandsaw blades is a fun project for any woodworker!

Our Certifications

Our Factory

Hangzhou Wagen Precision Tooling Co.,Ltd is a wholly-owned subsidiary of Ferrotec China Group, a Japanese diversified multinational group. It was established in 2000 with a total investment of 867 million yen. It is a research and development, production and sales of WAGEN brand metal cold saws and aluminum alloy saw blades. , tungsten carbide saw blades and diamond tools and other high-end precision cutting tool products are widely used in automobiles, aircraft parts manufacturing, aluminum alloy profile processing, furniture manufacturing, wood processing, plexiglass processing and other industries.

Ultimate FAQ Guide to Saw Blade

We're well-known as one of the leading saw blade manufacturers and suppliers in China. With abundant experience, we warmly welcome you to buy or wholesale high quality saw blade at competitive price from our factory. Contact us for quotation.